Typical Applications of Tungsten & Molybdenum Products

Our tungsten and molybdenum products find extensive use across various industries, acclaimed for their exceptional performance in mechanical manufacturing, oil drilling, medical equipment, vacuum furnaces, sports equipment, and welding, among other applications. Their versatile usage extends beyond these examples, prompting a deeper exploration of their potential.

Mechanical Manufacturing

The advantages of tungsten alloys includes unique hardness, ware-resistance, high density and tungsten melting point is very high.Tungsten steel alloy can withstand strong mechanical stress and extreme tempreture without the deformation and damaged. Tungsten application in machanical manufacturing is widely promoted, such as tungsten carbide inserts for precision machined components production.

Oil Drilling

Tungsten alloy should be good choice for material of dill bits and drilling rods. Tungsten alloy is a type of metal material with high strength, high density, and high melting point. It offers exceptional performance under extreme underground conditions, that makes drill bits rapid and effective drilling tools in petroleum drilling.

Vacuum Furnace

Vacuum furnaces demand intemal components to have a high melting point.For this reason,mosi2 heating element could be widely used for industrial and laboratory furnaces, which has the characteristics of high temperature oxidation resistance, excellent corrosion resistance and high melting point. In addition,tungsten alloys are often used for manufacturing tungsten electrode and other heating elements.

Sports Equipment

Tungsten is a very useful element in some sports equipment. For instance, high-end golf clubs and darts frequently use tungsten alloy for weight and balance adjustments. Additionally, tungsten is employed in certain pieces of jewelry, like tungsten rings, owing to its scratch-resistance and luster.

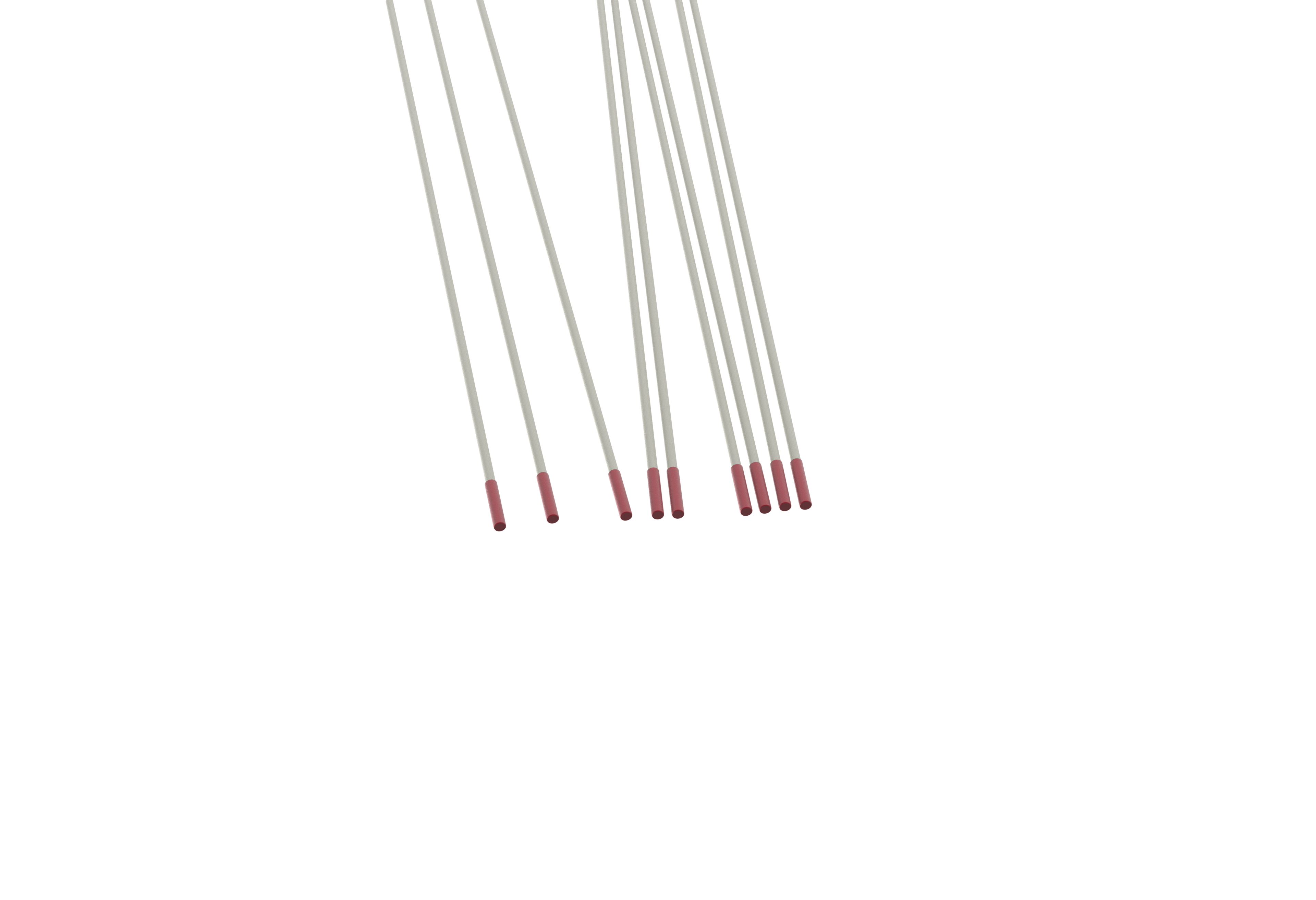

Welding

In welding, tungsten electrodes are extensively utilized due to their high melting point and excellent electrical conductivity, especially in Gas Tungsten Arc Welding (GTAW), commonly known as TIG welding. Tungsten electrode produces a stable arc, resulting in cleaner and more uniform welds. The stability of the tungsten alloy ensures that the electrode doesn't melt or deform easily at high temperatures.